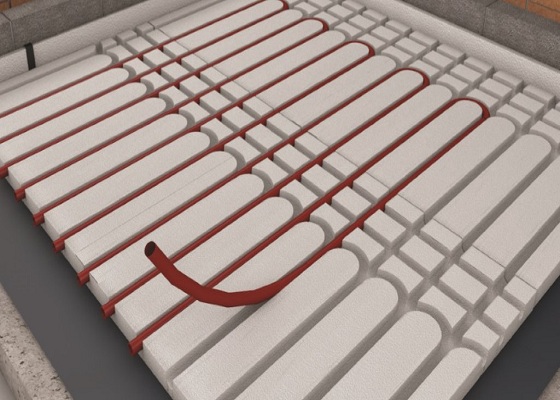

People can build houses on the top of the mountain, in the deep forest, in the Antarctic or the Arctic, thanks to insulation board technology. After the invention of polystyrene, it has been used as a thermal insulation board for houses because of its stable and good sealing properties.

Objectively speaking, we can’t deny the convenience that polystyrene brings to people’s lives, but we also need to see the disaster that this material brings to people’s lives. An insulation board is cut from the large pieces of polystyrene produced, which produces a myriad of polystyrene waste. The final destination of these wastes may be landfills or recycling companies, depending on the choice of the company.

However, these choices are flawed. Because of the volume problem of polystyrene, the transportation cost to landfills becomes a big expense. Recyclers will also collect large amounts of garbage because of the difficulty of plastic recycling. Processing costs. For a long time, the cost of insulation board manufacturers will remain high.

In the United States, a manufacturer of insulation boards has chosen a new way to recycle polystyrene waste on their own. After learning that polystyrene are recyclable, the company contacted INTCO Recycling, a recycling specialist who sells recycling machines to provide customers with a complete polystyrene recycling program. The manufacturer chose to purchase the polystyrene compactor, which is specially used to recover the cutting waste of the insulation board. The recycling machine can compress the polystyrene in a ratio of 50:1, and compress the large piece of polystyrene waste into a dense recycled polystyrene block, which saves the payment. It not only saves the fees charged by the recycler, but also improves the transportation efficiency.

The reason manufacturers are willing to accept this new approach is that recycled polystyrene blocks can be sold as commodities, which is equivalent to converting waste into profit. It is also true that recycled polystyrene blocks can be made into park benches, frame houses, etc., with a vast end market.

Rather than introducing a machine, the insulation board manufacturer introduced a new profit model, which is a very friendly way to the environment and producers.