In 2019, global plastic production reached 400 million tons. Despite a slight decline in plastic production in Europe, total production in 2018 was still 65 million tons. With the promotion and application of energy saving, the consumption of thermal insulation materials in various industries also increases year by year. Polystyrene foam plastic, the main application is in packaging for protection and shock absorption materials and building for thermal insulation materials. According to its production methods, there are molded polystyrene foam (EPS) and extruded polystyrene foam (XPS).

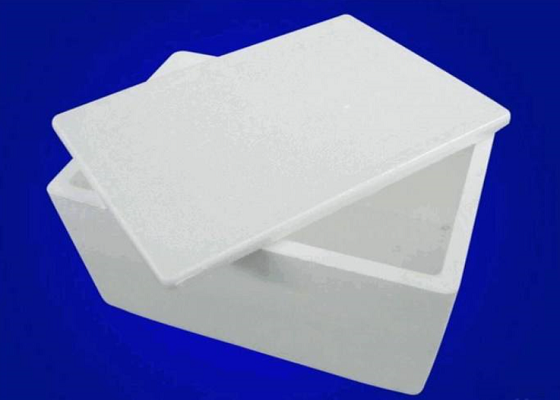

Why choosing EPS package?

The first advantage is density, which directly determines the weight of the package. According to the different needs of the product, the small-density package is more popular in most cases, because it can reduce the type of package, reduce the consumption of raw materials, and reduce the transportation cost and cost. The second advantage is shock-proof. The development demand of modern logistics industry is gradually diversified. Packaging materials with seismic function are increasingly popular. Because of these characteristics, many manufacturing companies wouldchoose to use EPS material for bubble formation, but handling the problem with profit maximization is always a difficult problem.

How to deal with EPS package?

In the previous case, there is a fish processor company in Denmark using foam densifier machine to deal with their EPSfish boxes. Large number of trashes were produced in this factory, and they had to spend lots of labor and time to handle this problem. Styrofoam compactor offers solutions designed to minimize waste in industrial companies of all sizes. Therefore, from small manufacturing and food processing sites to large production warehouses. These sites handle a wide variety of continuous waste daily, the most space-intensive of which is EPS foam. Foam densifier from INTCO RECYCLING ensures that you minimize the loss of wasted time, space, or money by reducing this waste at source.