Nominations for this year’s Waste Innovation and Recycling Awards have been extended through Tuesday, Aug. 31. the Prime Creative Media Waste Innovation and Recycling Awards is an ongoing sponsorship of the Women in Waste Awards to recognize women’s contributions to reducing waste and increasing resource recovery as we move to a more circular economy. This not only shows respect for the female community, but also highlights the importance of waste recycling as well as the circular economy.

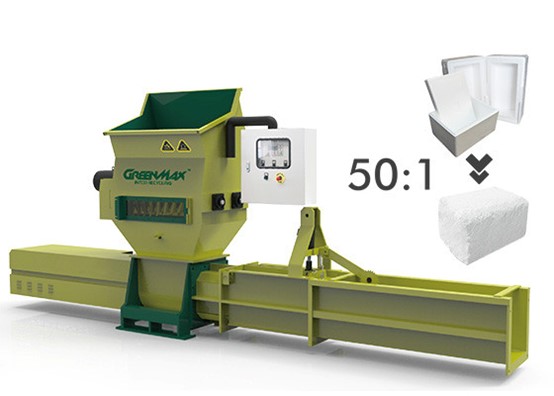

Take the most typical example of waste EPS, which was previously recycled by landfilling and incineration. These two methods not only bring pollution and impact to the environment, but also do not allow for in-depth implementation of sustainable development. Happily, it has been discovered that EPS can be 100% recycled by squeezing the air out of it. All you need is a professional GREENMAX EPS recycling machine to make EPS recycling twice as easy.

Mainfreight, a leading global logistics company, generates 70-100 cubic meters of waste EPS waste per week from opened white goods and furniture packaging due to appliance shipping. After using EPS compactor for some time, Mainfreight’s director praised that EPS recycling not only saves NZD 50,000 per year in waste disposal bonuses, but also brings in almost NZD 2W per year. This also contributes to the protection of the environment.

Having an EPS compactor can save considerable labor costs and transportation costs, after all, the headache of EPS is the large size and low density. After the recycling machine EPS into the raw material of PS particles are made into beautiful picture frames, skirting and other frame products are sold back into our lives, this process is very much in line with today’s sustainable economy. So, let’s take action and actively cater to the general trend of circular economy and waste recycling