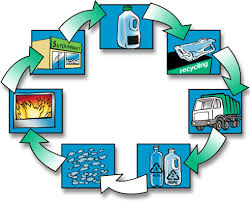

Some cans, plastic bottles, which can be discarded in the trash, if after recovering together will be a lot of minerals. One ton of waste plastic can be refined out of 600 kg of gasoline and diesel fuel, largely to save resources.

With the increasing depletion of natural resources and raw materials prices continue to rise, increasing the production of secondary raw materials by industrial producers of attention. The use of recycled plastics production, can effectively enhance the competiveness of the industrial producers from dual economic and environmental dimensions, compared to the new plastic, recycled plastic as raw material for production can be reduced 80-90% of energy consumption.

However, the recovery of waste plastics is less than 25%. On the status of the low recovery rate of waste plastics, French Suez Environment Group CEO Jean-Louis Xiao Sade December1, said waste plastics recycling and reuse market has a huge potential for development.

Plastics manufacturer giants will enter into plastic recycling industry.

Waste plastic recycling industry problem exist and they can’t be ignored.

Spawned the formation of massive accumulation of waste plastics recycling industry. However, the recycling industry looks beautiful, but in practice a lot of problems can’t be ignored. Although the market situation is good, but the production of renewable materials are relatively strong demand in the market is very weak.

At present, China waste plastics recycling industry exists enterprises and processing enterprises generally smaller scale, scattered layout, many domestic and foreign plastic recycling and processing of new technology and new equipment is difficult to promote the implementation of the recovery and processing of products of low quality and other issues, if not timely coordination, renewable materials industry will be extremely detrimental.