Rigid polyurethane is a highly cross-linked thermoset material. Most cell structure is closed-cell, and a few openings are for special occasions. In general, the recycling of rigid polyurethane foams are the following methods: grinding, physical recovery, chemical recovery, and combustion heat recovery method.

Pulverization treatment.

Polyurethane scrap and old scrap need to cut at first, and then need to be pulverized. Generally, rigid polyurethane foam could be easily pulverized. So the crushing technology is more mature, and most have been put into commercialization.

Recycling.

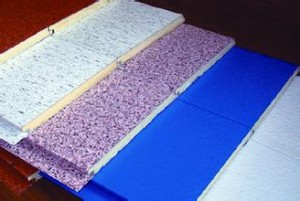

Physical methods recycling for polyurethane material is a method of changing the physical form after the direct utilization of waste materials. Physical recycling methods are thermoforming, bonding press molding, extrusion molding, and used as a filler, etc. Compression molding adhesive polyurethane scrap is the most common recycling methods.

The key points are: first, rigid polyurethane foam need to be pulverized into fine flakes, dusted polyurethane adhesive, and then turned into water vapor and other high-temperature gas. The polyurethane adhesive can be cured into a certain shape under pressure.

Polyurethane foam has excellent waterproof, vapor barrier properties, and the material does not contain water. In addition, water absorption of the material is very low, so the wall could maintain a good, stable adiabatic conditions, which is the point that the other insulation materials hard to achieve. Also, the material could withstand the most severe local climate and its changes.

After a long-time exposure and sudden rain, the external wall surface will not cause damage. The impact-resistant performance is better than other insulation materials.