With the great development of global economy and industrialization,

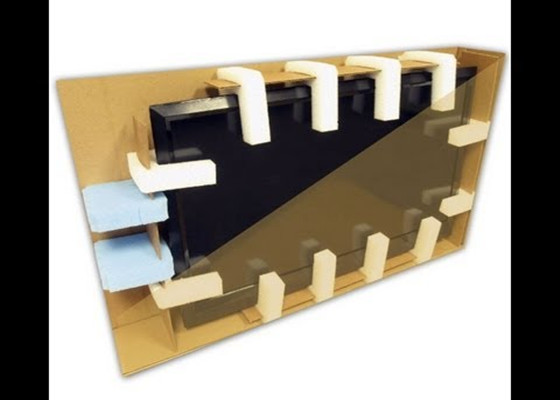

electronic product is no longer unreachable for ordinary people,since expanded polystyrene foam has great thermal insulation,lightweight and cheap convenience, this sort of plastic material has been largely used in home appliance packaging,especially such as LED monitor,refrigerator and extractor hood,but, the economy is a double-edged sword,more and more white pollution has been created due to the overuse of polystyrene disposal.

It is known that polystyrene is 98% air, only 2% of the product, 50000 tons of polystyrene products are an impressive material that is collected and recycled from home and businesses all over the country. However, polystyrene is a kind of lightweight material which makes it difficult and uneconomical to transport to recycling plants because the transport fee is costly. INTCO manufactures and sells GREENMAX EPS Screw Compactor or melter and Recycling machines or System, purchases back compressed EPS scraps, and reuses them to make frame products.

A 2013 industry report estimated that the lowest-cost alternatives to styrofoam would cost an estimated at $91.3 million annually. According to the Independent Institute, “For every $1 spent on foam containers, alternative packaging will cost food vendors $1.94.

Thus,it is hightly recommend that civil residents can do styrofoam recycling on their own,

when you buy the home electronics,if you have the packaging foam left at home, please help collect and contact local foam recycling organization so as to divert those polystyrene disposal from landfilling or being burnt, polystyrene recycling will lead to great reduction of white pollution,not only good for the enviornment,but also good for recycling industry.