What is PS, and What is it Used For?

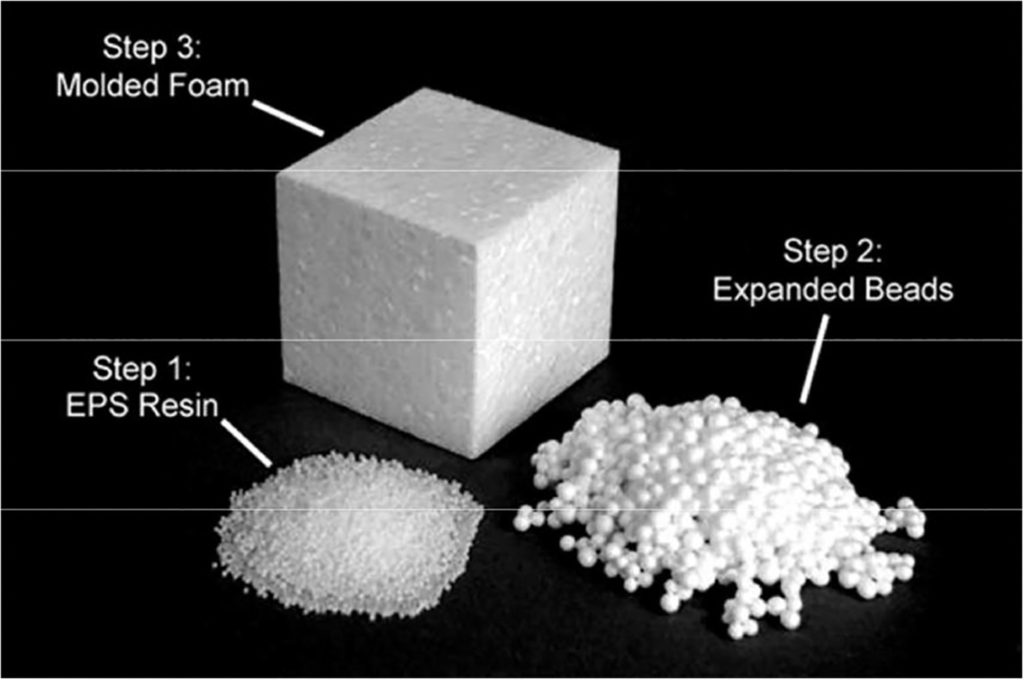

Polystyrene (PS) plastic is a naturally transparent thermoplastic that is readily available as both a typical solid plastic as well in the form of a rigid foam material. PS plastic is typically utilized in a range of customer item applications and also is especially beneficial for industrial packaging. As a hard, strong plastic, it is usually used in items that require clarity, such as food packaging as well as laboratory ware. When integrated with numerous colorants, ingredients, or other plastics, polystyrene is made used to make devices, electronic devices, car components, toys, gardening pots, equipment, etc. Dow Chemical Firm invented an exclusive process to make their trademarked and well-known polystyrene foam item in 1941. The material is rather controversial amongst environmental teams because it is sluggish to biodegrade and also is increasingly existing as outside litter (particularly in the form of foam drifting in waterways as well as the ocean).

The foam type of polystyrene is utilized frequently as a packing product. You have actually most likely unloaded a personalized styrofoam housing if you’ve ever acquired a brand-new television, or a significant item of new tools like a Miter saw. In a similar way, you’re probably familiar with styrofoam packaging “peanuts” made use of as filler for assorted tiny things being delivered. Styrofoam is additionally utilized for “to-go” containers as well as disposable tableware from numerous dining establishments.

Why is Polystyrene used so often?

Polystyrene is most distinctly useful for its application as foam. It is the runaway leader in the packaging market however it also has a variety of uses as traditional plastic. For years Polystyrene was used as the go-to prototyping material – basically for the same reasons we now use ABS. It’s low-cost, easily available, white in color, and also it glues, sands, cuts, and also paints well. The “S” in ABS is Styrene. A lot of older engineers and designers who have been in the market for some time will ask for a Styrene model when they’re looking for a quick-down-and-dirty model.

What are the Properties & Characteristics of Polystyrene?

| Property | Value |

| Technical Name | Polystyrene (PS) |

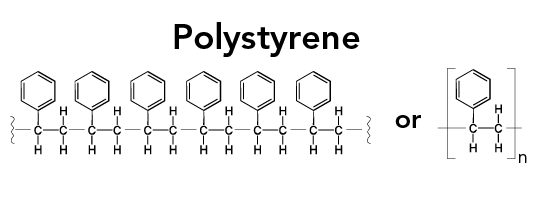

| Chemical Formula | (C8H8)N |

| Melt Temperature | 210-249 °C (410-480 °F) |

| Typical Injection Molding Temperature | 38 – 66 °C (100 – 150 °F) |

| Heat Deflection Temperature (HDT) | 95 °C (284 °F) at 0.46 MPa (66 PSI) |

| Tensile Strength | 53 MPa (7700 PSI) |

| Flexural Strength | 83 MPa (12000 PSI) |

| Specific Gravity | 1.04 |

| Shrink Rate | 0.3 – 0.7 % (.003 – .007 in/in) |

Polystyrene Characteristics

- Polystyrene has reasonably high melting points, which is 210 levels celsius.

- The expanded polystyrene has polycarbonate or thermoset qualities as well as could be reheated and also molded into various forms without considerable deterioration.

- The manufacturing cost of expanded polystyrene is low, and its dimensional stability is solid sufficient to hold modest pressure and also weight.

- The expanded polystyrene is 100% recyclable as well as reused for different objectives.

What are the Disadvantages of Polystyrene?

Polystyrene is the extremely inert definition that it does not respond specifically well with either acidic or basic solutions. This characteristic causes polystyrene to last a very long time in the natural environment which postures a litter threat as the material is normally gotten rid of after an exceptionally brief valuable life-span. Therefore, to avoid polluting the environment, polystyrene ought to be recycled and also reused sensibly, GREENMAX can offer one-stop polystyrene recycling solutions for you. GREENMAX has actually launched 4 series of waste recycling devices: eps compactor, hot melter, foam crusher, and beverage dewatering equipment. Applicable products consist of EPS, EPE, EPP, and beverage packaging.