Currently, the recyclability of PET bottles has almost become everyone’s consensus. Some unqualified products produced by plastic bottle factories can be put into the production line again through the recycling process, saving the consumption of raw materials. And waste PET bottles can be converted into PET recycled particles through PET recycling, which are manufactured into food-grade packaging and clothes.

PET recycling can divert a large amount of waste PET bottles from oceans and landfills, realizing the reuse of resources and reducing the negative impact on the environment. PET recycling is not a simple investment without return, but an investment with high returns. The PET recycling process includes collecting, dewatering, baling, washing, sorting, crushing, second washing, and granulation. Waste PET bottles are collected and transported to a recycling company, where they will be flattened and baled and the liquid in the bottles will be removed. And then, through washing and sorting, different materials of bottles are classified and become clean. After being crushed into uniform pieces by a plastic crusher, PET bottles will be cleaned and dried. At last, through being hot melted at a high temperature and granulation process, plastic bottles will convert into PET particles, becoming a renewable resource and used for making recycled products. The products of the whole process can be sold to a downstream recycler for subsequent recycling and processing.

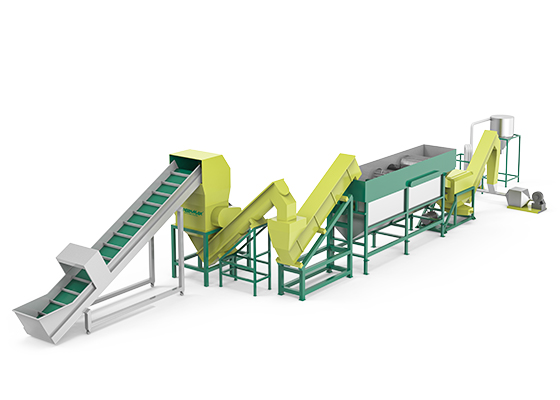

Washing is quite an important part of the whole PET recycling process, which will influence the purity and production capacity of PET particles, and recycling efficiency. GREENMAX plastic washing line is a large complete set of equipment, suitable for the solid waste recycling industry and can help companies improve their sustainable waste management ability. This plastic washing line is able to process various renewable solid waste plastics such as HDPE, PP, PET bottles and so on. And this equipment uses advanced washing technology, with the advantage of high efficiency and energy saving, which can improve production efficiency and reduce labor costs. The production capacity of GREENMAX plastic washing line is 400-500kg/h, confirming the recycling requirements of customers perfectly.

Most importantly, GREENMAX as a global leader in high-tech manufacturing through recycled materials, has mature research and practice experience in PET recycling. We can provide customers with a one-stop PET recycling solution and a professional plastic washing line. According to actual situations and recycling requirements, GREENMAX can customize PET recycling solutions for customers. This is also one of our advantages that has won the favor of many recyclers and large enterprises. Additionally, GREENMAX can supply global customers with sales solutions for PET particles, helping them sell particles. We provide a particle buy-back service at a preference price or other local sales channels of PET particles for customers. These PET particles will be used to remanufacture mirror frames, environmentally friendly floors, and other recycled products realizing the close loop of PET recycling.