EPP waste materials can be recycled mechanically to achieve resource reuse. The EPP foam recycling process involves EPP compactor, EPP granulator and other EPP recycling machines, which can well transform foam into high-quality recycled materials and are a sustainable solution for EPP.

As a leader in the field of EPP foam recycling, INTCO Recycling has independently developed a professional GREENMAX EPP recycling machine that can meet the market demand for high-quality recycled materials and can make the quality of recycled materials meet international standards.

How do EPP recycling machines implement EPP foam recycling?

EPP foam recycling needs to go through the processes of collection, sorting, cleaning, compaction and granulation to transform the foam into recycled materials. First, the EPP foam is collected and simply cleaned, and contaminants such as tape need to be removed, and then it will be sent to a special EPP foam recycling company. There, the EPP foam will be professionally recycled and processed into reusable materials, such as compaction and granulation. EPP foam has a high hardness and low density. If it is directly transported by truck or container, it is obviously expensive and inefficient. Therefore, the EPP recycling machine is first required to reduce its volume. GREENMAX EPP compactor will compact it into dense foam ingots at a high ratio. After the granulation process of EPP granulator, the foam ingots are processed into granules, which can be used to make a variety of products.

The working steps of EPP recycling machine.

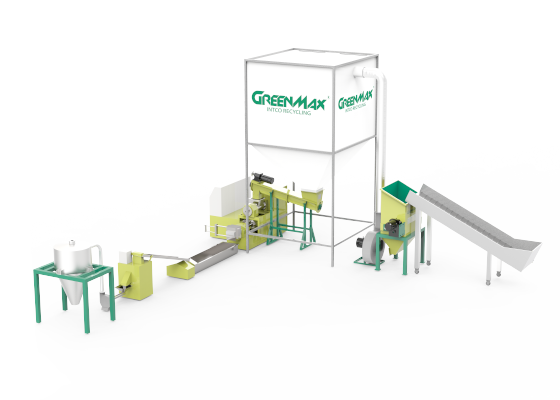

The whole process of EPP foam recycling mainly involves two EPP recycling machines, EPP compactor and EPP granulator. EPP compactor is mainly used to compact the volume of foam for subsequent transportation and storage. GREENMAX EPP compactor can compact EPP foam into foam ingots at a ratio of 50:1. The material compatibility of this machine is very high, and it can be used for multiple purposes. In addition to EPP foam, it can also process EPS, XPS and other foams. If you have other types of foam recycling plans in your future development, this EPP recycling machine can meet your recycling needs and help you save machine investment.

EPP granulator melts the foam at high temperature and processes it into granular form, which can realize one-stop EPP foam recycling. The EPP recycling machine is an integrated system that combines crushing, compaction, granulation and other functions. Large pieces of foam are sent to the crushing bin of the EPP recycling machine through a conveyor belt and broken into uniform fragments by a screw cutter. Then, the EPP foam fragments are melted into compact foam ingots at high temperature in the compaction bin of the EPP granulator. The screw will stir and convey the hot-melt foam, and the foam ingots will be extruded in strips through the filter screen and die head. This EPP recycling machine is equipped with a filter screen to filter out some impurities and ensure the purity of the recycled particles. The strip foam ingots need to be cooled in a water tank, then cut into granules and packaged.

If you have any questions about EPP recycling machine, INTCO Recycling will be happy to answer you.