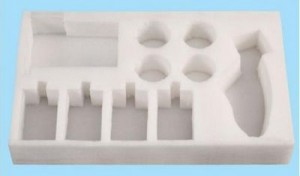

Polyethylene foam is a high-strength buffer, anti-vibration capability of the new environmentally friendly packaging materials. It uses butane foam molding and addition of two materials, industrial or medical drain ultrafine talc materials and food pumped anti-shrinkage agent monoglycerides, the entire production process for the physical changes. So EPE is non-toxic, environmentally friendly, EPE foam has a high elasticity, and full of tough but not brittles, which is currently the more advanced, environmentally friendly interior materials.

The surface is soft, pleased to the eye, with light, heat, vibration noise, corrosion resistance, anti-static agent pink EPE raw materials. Also, the material has significant anti-static function because of its light weight makes enable packaging products to reduce transportation costs greatly.

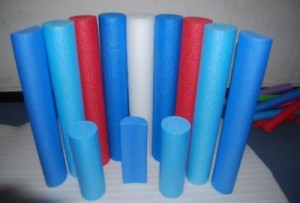

Polyethylene foam is an easy processing and handling of materials. EPE foam is generated by the high-pressure polyethylene foam countless sealed bubble physically constituted an expansion ratio of 30-40 times of the semi-rigid foams. The appearance of EPE foam has a variety of shapes, sheet, coil, tube, and rod. EPE has good shock, dust, moisture, heat insulation, sound insulation, thermal insulation, anti-acid, and anti-static properties.

INTCO have PE foam recycling machines which could handle and recycle waste polyethylene foam. As waste polyethylene foam have pollution on the environment, Greenmax machines could handle them and to prevent the environment being polluted and resources wastes.