Moisture resistance – If you’ve ever had the misfortune of getting caught in the rain without a coat, you know that a wet shirt does a poor job of keeping you warm. The same is true with insulation—when damp it becomes much less effective at keeping heat in a building.

An insulation’s moisture performance is crucial anywhere in the building envelope, but especially so in below grade applications, as these areas often are in contact with damp earth.

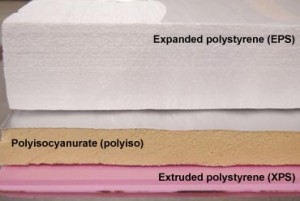

EPS and XPS insulations perform very differently when it comes to moisture. EPS tends to absorb small amounts of moisture quicker, but also releases it much faster than XPS does. This has led to confusion about which material performs best, as XPS comes out ahead in the laboratory, while EPS is superior in real-world applications.

Both insulations commonly are evaluated per ASTM 272, Standard Test Method for Water Absorption of Core Materials for Sandwich Constructions. In this test, insulation samples are fully submerged in water for 24 hours, then weighed for moisture absorption immediately upon removal from the water.

The problem is this test method is designed to ensure products are manufactured to required specifications, but does not adequately reflect real-world building conditions. Unless a building is subjected to extensive flooding, its below grade insulation is almost never fully submerged as in the laboratory test. And, unless such flooding is prolonged, the test doesn’t consider how insulation dries between periods of moisture exposure.

In-the-field tests of insulation exposure to moisture show that EPS outperforms XPS by a wide margin, largely because EPS dries much faster than XPS. In one of many examples, the independent lab Stork Twin City Testing evaluated the moisture content of EPS and XPS buried side-by-side for 15 years on a building foundation in St. Paul, Minnesota. At the time the insulations were removed, the EPS was four times drier than the XPS—the EPS had only 4.8% moisture by volume compared to 18.9% moisture content for the XPS. After 30 days of drying time, the EPS had dried to only 0.7% moisture by volume, while the XPS still contained 15.7% moisture.